Data-Centric Spatial Digital Twin

Connected Data-Centric

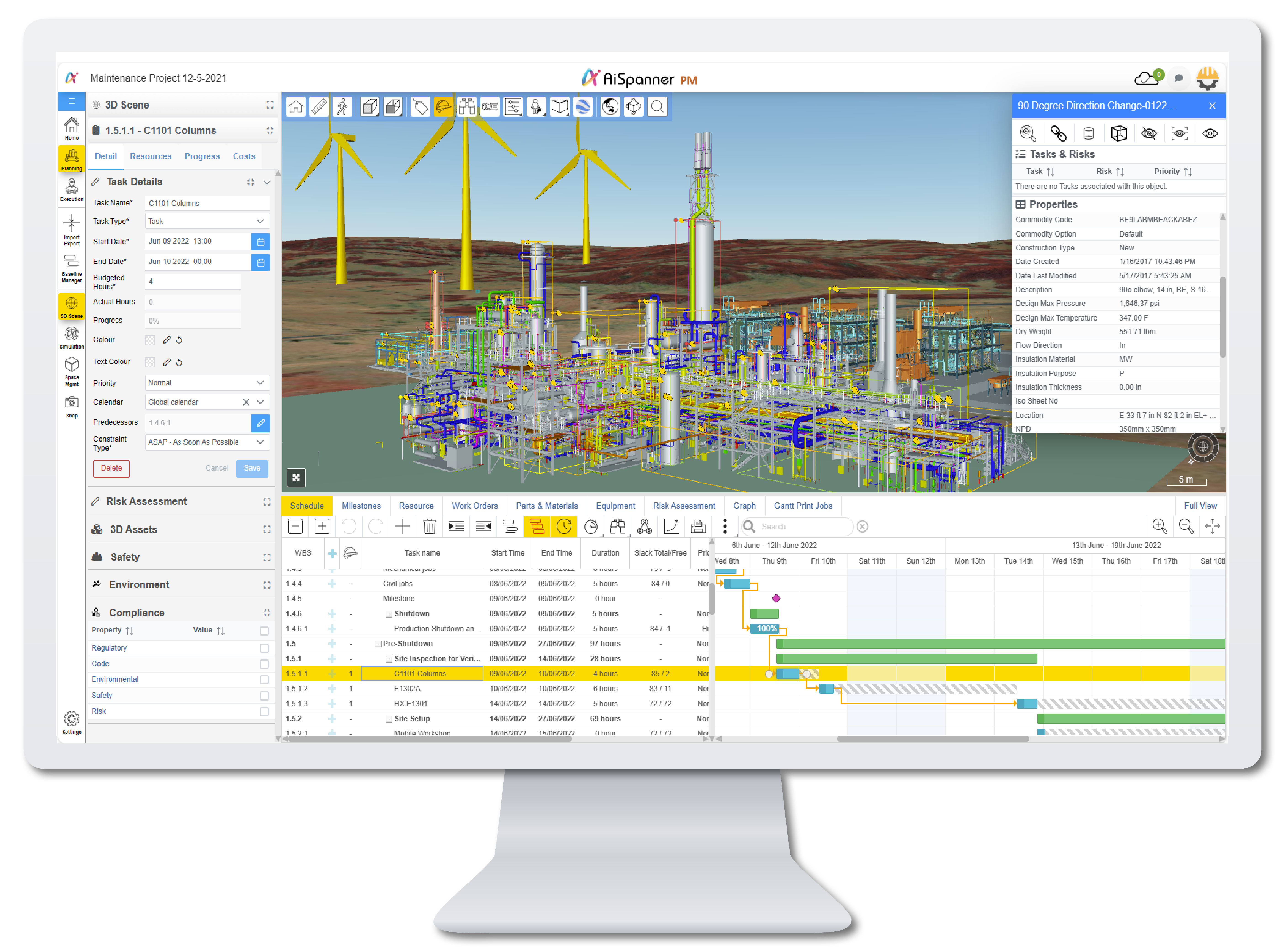

The AiSpanner maintenance project management platform is the foundation for developing connected data-centric digital twin, which creates a digital thread across the project functions that allow planning, scheduling, monitoring, tracking, analysing and integrating digital asset(data). This collaborative, data-centric digital environment enables project teams to effectively work in an integrated way, while providing insight into the connectivity between elements to aid project delivery certainty.

Standard data has little value. To become useful information for a decision maker, data requires context and relevance. Context describes the relationship of one piece of data to other pieces of data. AiSpanner uses graph database (Neo4j) to create knowledge graph by connecting 3D (Geometry) representations of assets with or without relevant reference data, engineering (structured, semi-structured or unstructured) and maintenance data with relationship (context) so that it can be efficiently ingested and processed to create intelligent data-centric digital twin for further actionable insights.

AiSpanner is easier for people across business functions to access and explore the data on their own. It enables 4D, 5D, Risk simulation and validation of schedules for maintenance projects. Whether the project is shutdown maintenance, a major refurbishment, lubrication planning or even inspection planning, companies can plan scheduled activities in detail and avoid the unforeseen problems that can result in expensive rework and schedule delays.

- Empower end users to experience and consume data in context.

- Improve data literacy through meaningful and actionable insights.

- Collaborate across stakeholders and capture hidden expert knowledge.

- A central, visualised model of information, makes it easy to find and understand.

- Contractor and subcontractor are given access to an unprecedented amount of useful information, empowering them to make smart decisions.

- Plan scheduled activities in a 4D environment by linking the schedule to 3D models for validation.

- Validate and optimise the project schedule by linking it to the 3D plant model.

Visualise - Simulate - Optimise

Connected Team

Data driven technology enables close collaboration between all disciplines, integrates processes and assures end to end continuity by sharing the same source of real-time information.

A single source of truth unlocks efficiencies, increases productivity and secures profitability via data driven processes and decision making.

- Workforce of the Future

- Emerging technology

- Collaboration & Communication

- Project Transparency

- Connected stakeholder

- Analytics

- Delivers project certainty

OFFICE

300 Murray Street, Level 2 East,

The Wentworth Building,

Perth WA 6000

Australia